News

On this page we want to introduce trade fairs, informative from our house or the latest developments in the field of glass production and stone processing. If you are looking for detailed information on the various topics, then please contact us.

Credentials

New bridge saw is now ready for use

The Schmalz company from Lauterbach now has a powerful replacement for the outdated old bridge saw.

With a Z-axis of almost one meter and saw blades of up to 1,000 mm, they can handle massive work now.

The machine was adapted to the existing foundations.

Relied on tried and tested

Diamond Wire Saw with a side grinding unit

Unique gravestones with freely planned contours are now being made in Straubing. This is possible by using the DKSS Diamond Wire Saw with a side grinding unit.

The first step is sawing, and the next step is grinding and polishing the contour. The workpiece only needs to be benched once

Wiesbaden

CNC – GLA-F Radial Grinding and Polishing Machine

In Wiesbaden it is now possible to process thicker workpieces.

In the Guckes Söhne company, the space on the column is again occupied by a GLA-F.

With a height adjustment of over 700 mm, workpieces such as steles can now also be processed.

The radial arm grinding and polishing machine was mounted at an existing solid column by a specially constructed intermediate piece

Relied on tried and tested

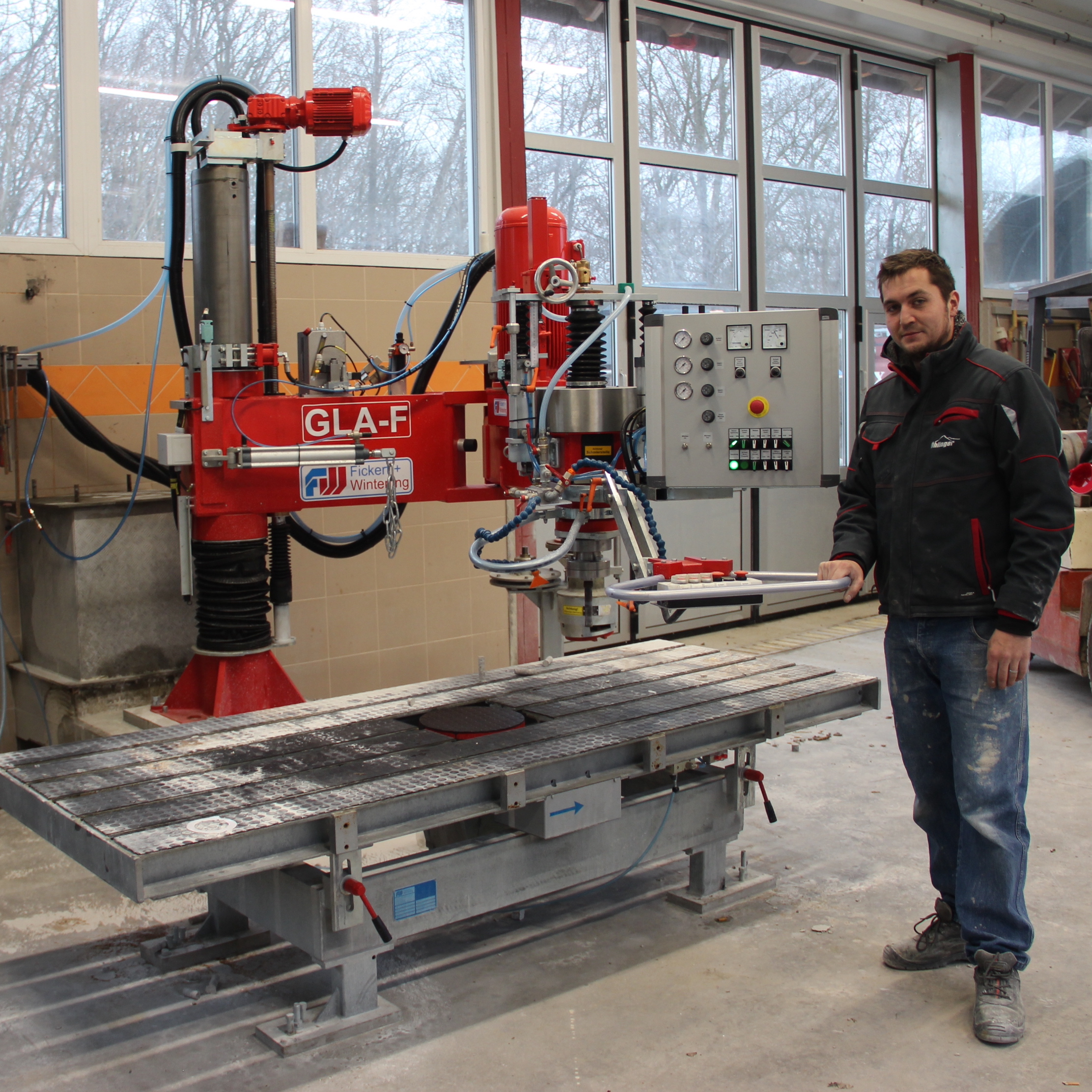

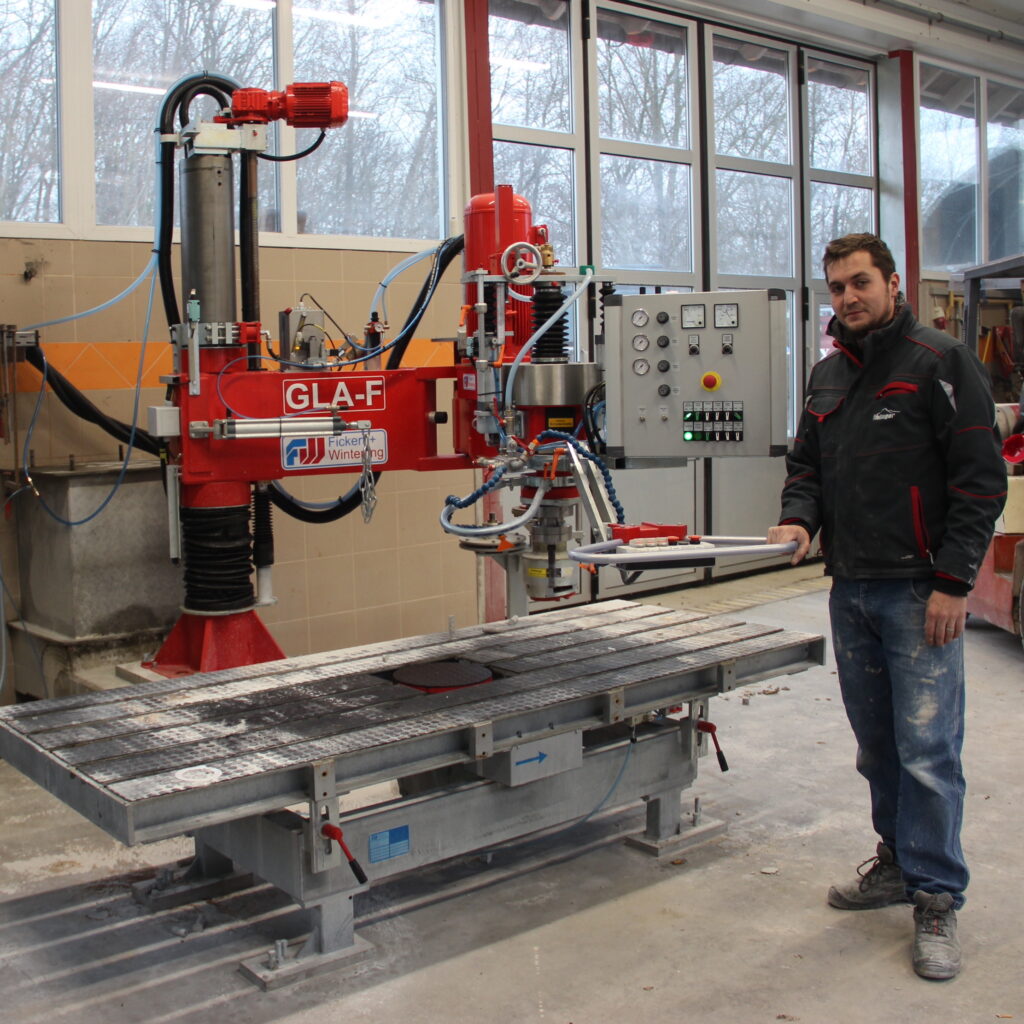

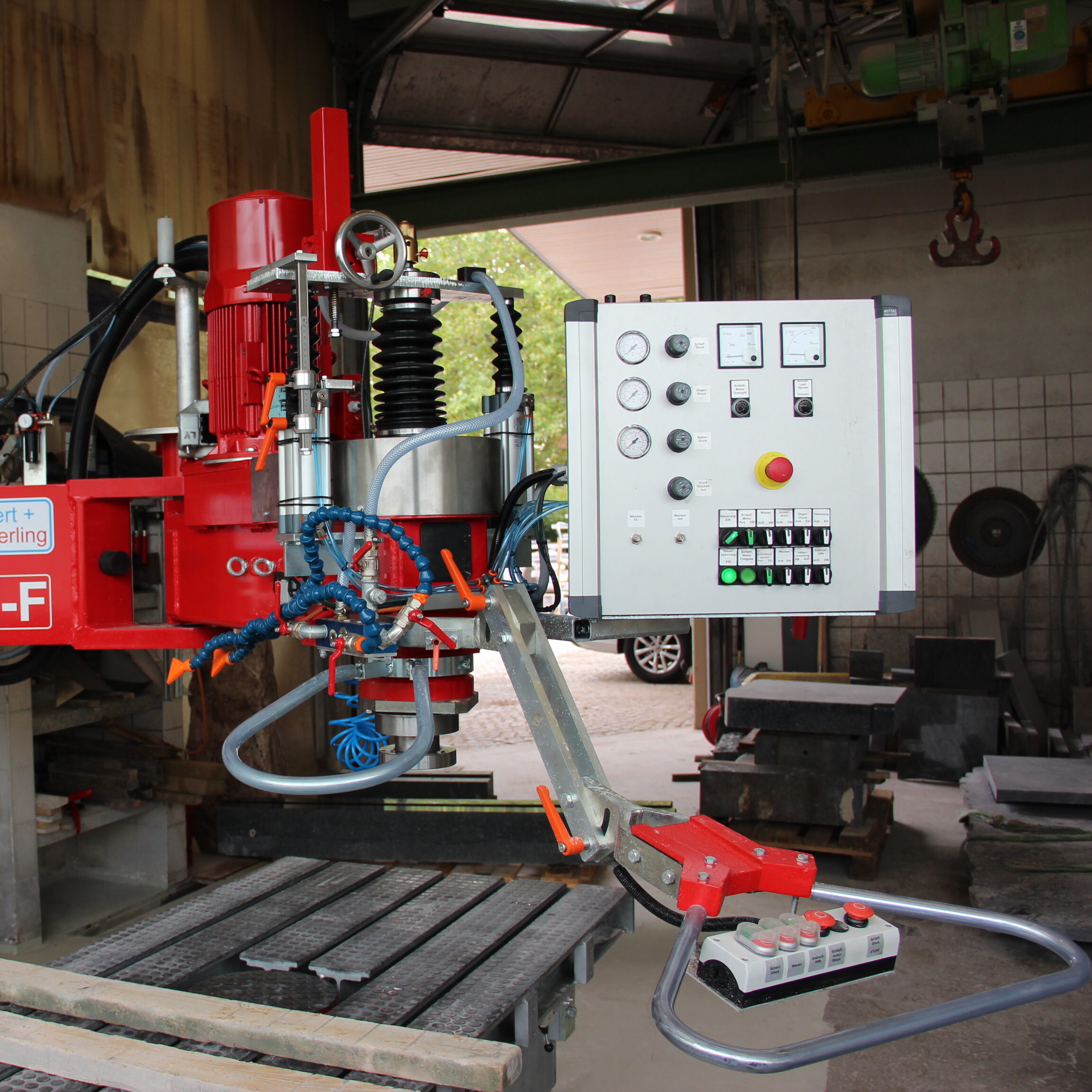

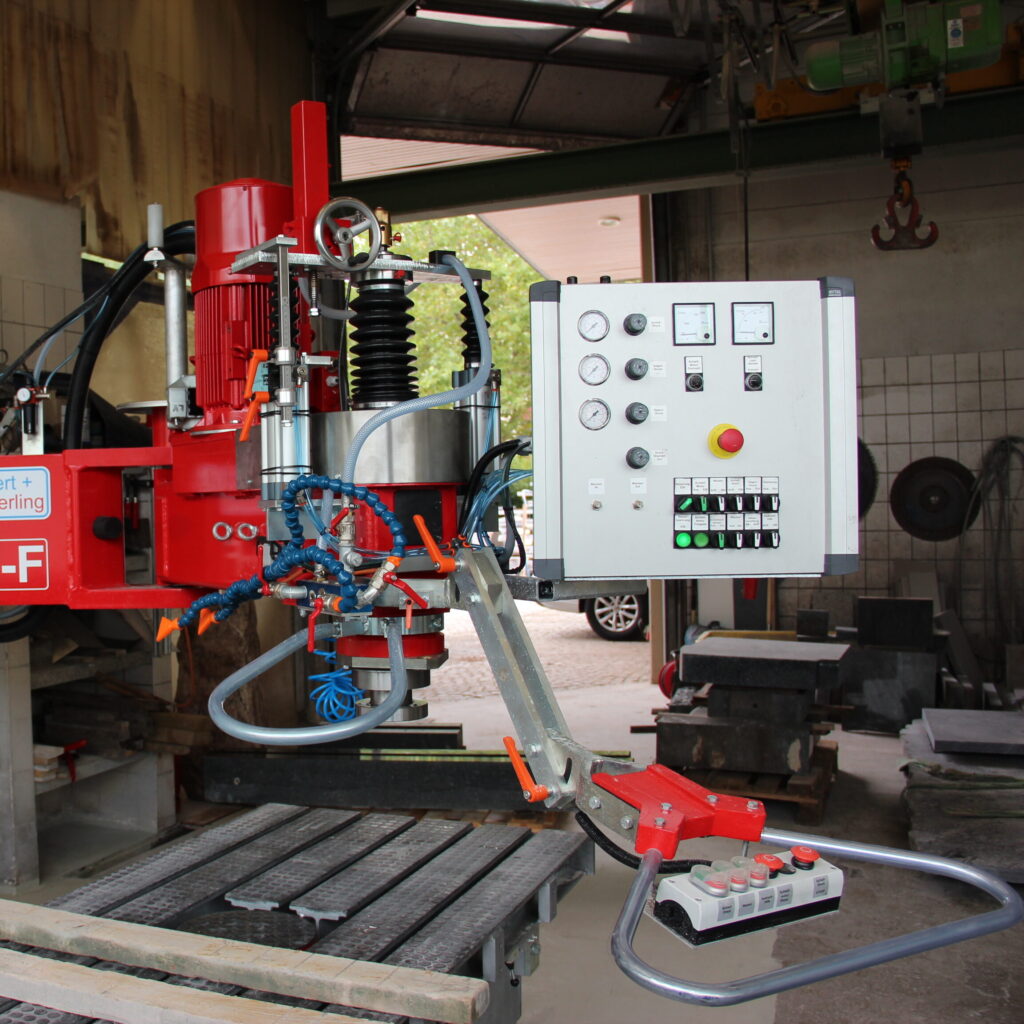

CNC – GLA-F Radial Grinding and Polishing Machine

The second radialarm grinding and polishing machine, type GLA-F, already arrived at the Grobe company in Bad Lausick.

After 26 years of reliable use, the radialarm grinding and polishing machine was replaced by the successor model.

With the lifting cylinder, integrated in the table, the tombstones can now be lifted, rotated and processed on all sides.

Precision work in Alfeld

Edge grinding machine Type KSA 722

The KSA 722 automatic edging machine had to be delivered to Westphal company in three parts to be assembled in the narrow hall. Such custom-made products are our strength, we always find an individual solution for the spatial conditions of our customers.

When the machine was handed over, Oberpfälzer Zoiglbier made sure that the company boss and the staff beamed.

New GLA-F mounted to existing grinding table

GLA-F Radial Grinding and Polishing Machine

The Jakobi company has replaced its veteran Thibaut with a new radial arm grinding machine type GLA-F.

By using the existing grinding table, no foundation work was necessary.

The machine can now also be used to machine the sides of the tumbstone without any problems. The lifting cylinder integrated in the table enables the workpiece to be turned freely.

A symbiosis of old and new

GLA-F Radial Grinding and Polishing Machine

A symbiosis of old and new at the Weber company in Achern, a new radial arm polishing machine was installed.

with a specially designed custom-made intermediate piece, it was possible to attach our GLA-F to the existing wall bed.

With the included high-speed spindle, cutouts for kitchen worktops can now also be made.

Room is in the smallest hut

GLA-F Radial Grinding and Polishing Machine

With millimeter precision, the mount for the articulated arm grinding machine was fitted in the workshop of the Küchenmeister company.

A static challenge was the attachment of the wall bed, but we were able to find a solution to the problem.

Now the own ideas for the gravestone design can be realized.

Happy faces on father and daughter

PFE type bridge saw

The Schneider company in Plauen has moved into its new production hall.

The heart of the new production is a CNC controlled bridge saw type PFE.

The powerful 17.5 KW motor drives saw blades up to a maximum of Ø 800 mm.

The sawing table is equipped with tilting forks, which allow convenient loading of the rough dimension plates with the forklift.

The articulated arm grinding machine, which is already available in the company, has also found its new place in the hall.

Now, according to own designs or customer specifications, all common natural stone works can be realized.

Mirror finish on narrow edges

Edge grinding machine Type KSA 722

DKSS Contour Wire Saw with side grind unit

Finally the gap in the machine shop is closed.

The company Plagemann now has a contour wire saw with side grinding unit. Now curved contours can be sawn out according to customer requirements and in the next step the outer surface can be ground and polished. This makes you less dependent on imported goods and allows you to supply customers promptly.

LA-F radial arm grinding machine

The Westmans Stenhuggeri AB company from Fjugestra, Sweden has got reinforcement in the machine park.With the GLA-F radial arm grinding machine, he has now closed a gap in order to make his gravestone production more effective. With the extensive accessories and many tools, many jobs can now be done faster and more effectively

A fresh splash of color in the workshop

CNC – GLA-F Radial Grinding and Polishing Machine

A contour wire saw in signal yellow now enriches the machinery of Strecker.

The CNC-controlled machine is used to saw out the contours of the gravestones and then grind and polish the side surfaces.

Now own designs or customer wishes can be realized promptly.

Bridge Saw Typ LBS 625

Company Brill

After decades of loyal service, the old Fickert saw was replaced by an LBS 625. This machine is designed to fit the old foundation from the gauge. With the touch screen for operation and control components such as the cutting sequence and last cut in the opposite direction, the sawing work can be carried out in a time-saving manner

New two-table sawing line put into operation

Bridge saw type PFE-160 a1 CNC

Growth in the machine park of the company SSW in Pirna.

A heavy mobile bridge saw of the type PFE-160 a1 CNC was accurately mounted on the existing foundations.

Equipped with a 30 KW motor, the Saxon sandstone, with a maximum thickness of 550 mm, can be cut with saw blades of up to Ø 1,400 mm.

When using smaller saw blades up to Ø 1,000 mm, the saw head can be swiveled 90 °.

Since the machine has two tables and correspondingly separately secured working areas, while sawing is going on in one area, benching can be carried out in the other area.

This makes efficient work possible

Bridge Saw with Turning Head Typ PDK

High-tech saw fitted into the hall with millimeter precision.

A modern PDK type rotary head saw has been installed in Algermissen. It was a challenging task to cope with the available space. But we succeeded in offering the customer an optimum solution on the tilting fork table, the dimension plates can be effectively banked. After being captured by the camera, the cuts are planned on the computer and the workpieces are precisely cut.